ProtoFab's origins go back to 1996, when former chemistry teacher Jack Wu started offering rapid prototyping services for the nascent industrial design market in China.

The company he founded, Duch Group, is now one of the world's leading manufacturers of custom prototypes and on-demand production services. With three manufacturing facilities across China, Duch Group is able to offer design assistance, rapid prototyping, low-volume manufacturing, and mass production to clients all over the globe.

Duch Group launched the ProtoFab project in 2014, offering industrial-grade stereolithography 3D printers fine-tuned for cost efficiency and offered as part of unrivaled production services package.

With two decades of offering on-demand production and rapid prototyping services, ProtoFab is the perfect partner for bringing ideas to life. We have a wide range of processes and materials to choose from, each with its own benefits and applications.If you have this requirement, please contact our professional team at [email protected] or contact us by visiting our website, we will provide you with a quote for free for the first time.

Quest 3D Printing ServiceProject name: Projector ModelMaterial: ABS、AcrylicProcess: CNC MachiningPost treatment: Sanding, Polishing, Painting, Silk ScreenAccuracy: 0.02MMSample type: PrototypeUsag...

For regular cyclists, one of the most important parts is the bike seat. It must have comfort, so that the bike can play a greater riding performance. Based on the knowledge of human mechanics, Vistar...

Inthe past two years, 3D printing technology has been widely used inarchitecture, medical, footwear, dentistry, aerospace and many otherindustries.Nowadays,it is also gradually used in furniture desig...

Jun 22,2022

There will be a stage of small batch production to test product performance and market demand before mass production generally. If it is a small batch trial production, vacuum casting is the best choi...

Read More

Jun 22,2022

There will be a stage of small batch production to test product performance and market demand before mass production generally. If it is a small batch trial production, vacuum casting is the best choi...

Read More  Historic Breakthrough! ProtoFab Welcomes the Milestone of 100 SLA3D Printers In One Day!!!

Historic Breakthrough! ProtoFab Welcomes the Milestone of 100 SLA3D Printers In One Day!!!

Jan 27,2022

On December 27th, at the end of the year 2021, ProtoFab have made a new breakthrough. 100 sets ProtoFab SLA 3D printing equipment were successfully shipped to the customer's large production line, whi...

Read More

Jan 27,2022

On December 27th, at the end of the year 2021, ProtoFab have made a new breakthrough. 100 sets ProtoFab SLA 3D printing equipment were successfully shipped to the customer's large production line, whi...

Read More  Building sand table model with 3D printing technology

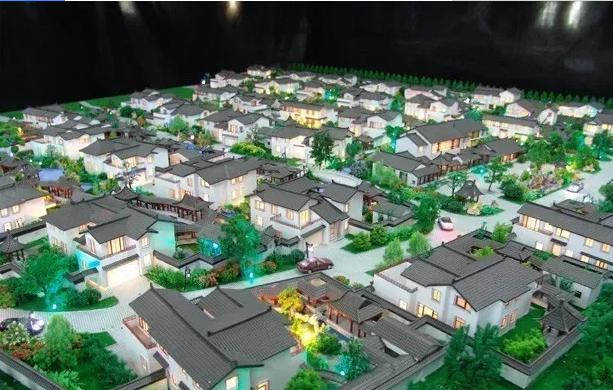

Building sand table model with 3D printing technology

Nov 18,2021

Shortcomings of traditional production methods:Taking the construction industry as an example, the traditional sand table production needs to make a graphic design sketch firstly, the production comp...

Read More

Nov 18,2021

Shortcomings of traditional production methods:Taking the construction industry as an example, the traditional sand table production needs to make a graphic design sketch firstly, the production comp...

Read More