Vistar 3D Printing Car Bumper

Name: Car bumper (Length: about 1.6M )

Process: SLA rapid prototyping, vacuum Casting

Uses: design, structural verification, Vacuum Casting

Manufacturer: Vistar(ProtoFab) 3D printing Printer

SLA1600

SLA1600 is a new ultra-large 3D printer developed by Vistar for the large-format requirements of the UV-curing 3D printing market. It has a large printing format of 1600×750×550mm, which meets the urgent demand of rapid prototyping field ,such as manual model making and car styling and design. it can achieve integrated printing large-scale prototypes, such as, car grilles, bumpers, dashboards etc. Effectively avoiding product errors and labor waste caused by splicing. At the same time, the rapid prototyping capability of Vistar UV-Curing 3D printers has increased Vistar production efficiency by more than 10 times

Production Process

1. Open the file of car bumper design and export the STL format data.

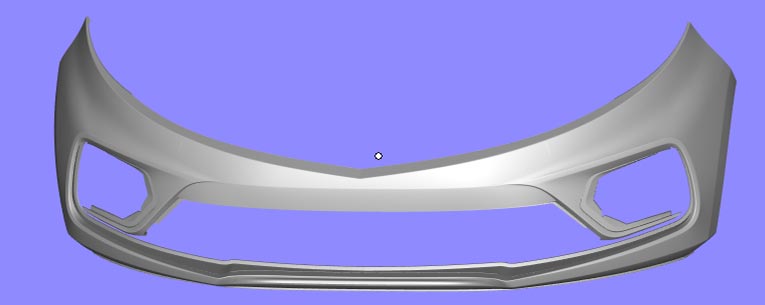

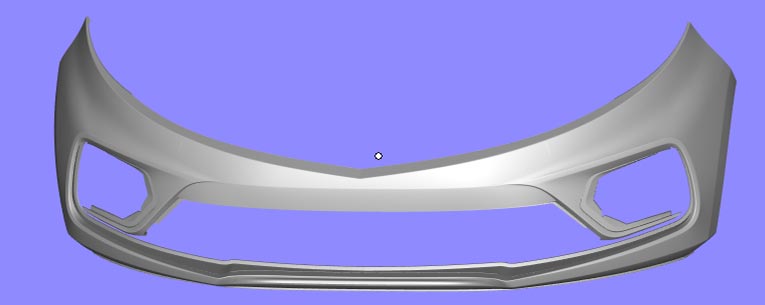

3D modeling diagram of car bumper

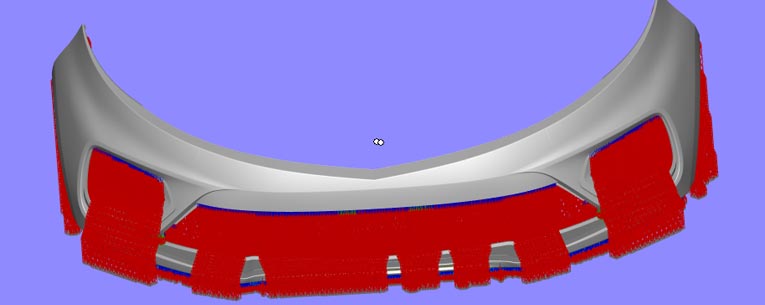

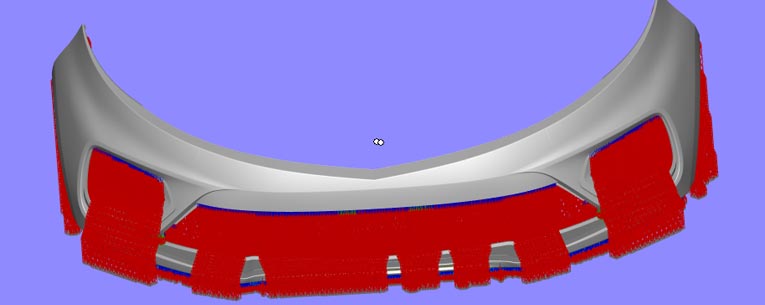

1.Import files into Magics software for slicing

Support

1.Import the processed three-dimensional documents into the printer SLA1600, and solidify the three-dimensional printing process without manual guard. At the same time, many kinds of structures can be designed and printed out in batches, and the best scheme can be obtained through one-time testing, thus ,reducing the time of repeated testing and proofing. Using Vistar 3D printer, the test data and final plan of the product can be obtained in 1-2 days.

Printing

2. cleaning and polishing the printed bumper model after printing

Polished parts to make the product more finer and smoother

3.The polished surface of the model is smoother, it is can be used for structural verification or as prototype for vacuum casting .

THE ADVANTAGES OF Sla1600

SLA1600 has a large printing format of 1600 × 750 × 550mm, equipped with high-end optoelectronic devices, combined with highly efficient and stable control software Sirius and the world's first DLC variable laser power printing technology, 3 field lens and 3 lasers (multi-field lens selectable ),Also ,it is combined with the self-developed variable spot technology, greatly improves printing efficiency and precision, and it takes only 10 hours to print a car bumper.

Conclusion:

Vistar's ultra-large 3D printers provide reliable and lower cost 3D printing solutions for the automotive, aerospace and other industries. The small batch of finished samples is an important part of the prototype trial stage. The quality of the prototype is especially important for the perfect tooling design and prototype test, so it must meet the short production cycle and high dimensional accuracy. Vistar combines 3D printing with vacuum casting together (vacuum casting and reaction injection molding ) to create a rapid mold manufacturing method that saves development costs and shortens development cycles.

Show Case of 3D Printing Auto parts

Auto Front Bumper

(SLA/Cacuum Casting )

AutomotiveGrille

(SLA/Vacuum Casting )

Car Headlights ( All-in-one )

(SLA/Aluminizing )

Auto Engine Cover

(SLA/Vacuum Casting )

Automobile Exterior Design Model

(SLA/Spray paint )

Automobile Pillar

(SLA/Spray paint)

Automobile Air Conditioning

(SLA/SLS/Vacuum Casting /Spray paint )

Auto Storage Box

(SLA/flocking)

Car fuel tank cover

(SLA/Spray Paint )