Case Analysis of 3D Printing Metal Octopus Model

Project Name: 3D printing metal Octopus

Manufacturing process: SLM selective laser melting

Printing material: metal powder

Service provider: ProtoFab 3D printing

Recommended model: SLM150

Print size: 150 * 150 * 100mm

Equipment advantages: 3D printing integrated molding, fast printing speed, high precision, good surface quality, high density of parts

Period: 2 days

Purpose: appearance design, structure verification, model decoration

Project analysis

After receiving the 3D drawings sent by the customer, according to the requirements specified by the customer, the pre analyst analyzes the process and develops the production process. The structure of octopus tentacles is complex, the joints are closely linked, and the degree of freedom is very high. 3D printing is very suitable for printing such difficult design works. For complex hollow or nested multi-layer structures, traditional technology is difficult to achieve. 3D printing can quickly and perfectly present complex structures, which can be formed in one time. It greatly reduces the production cost and shorten the production cycle. After the evaluation, we choose SLM selective laser melting process to realize the integration of the model.

Production process

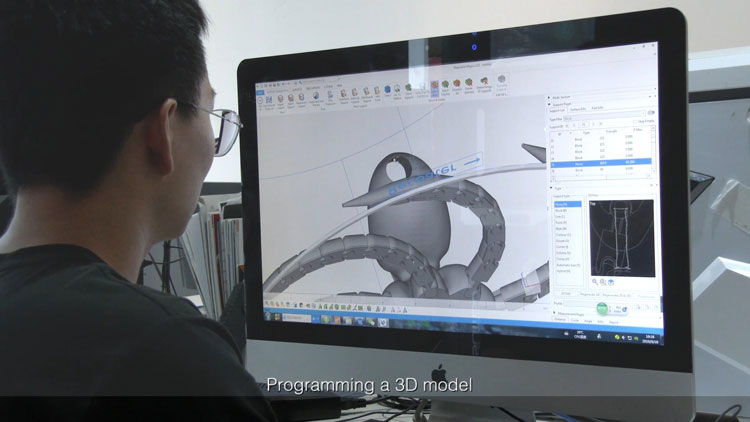

1. Help customers to optimize the design structure, export STL format data file, and then import the magic software for slicing;

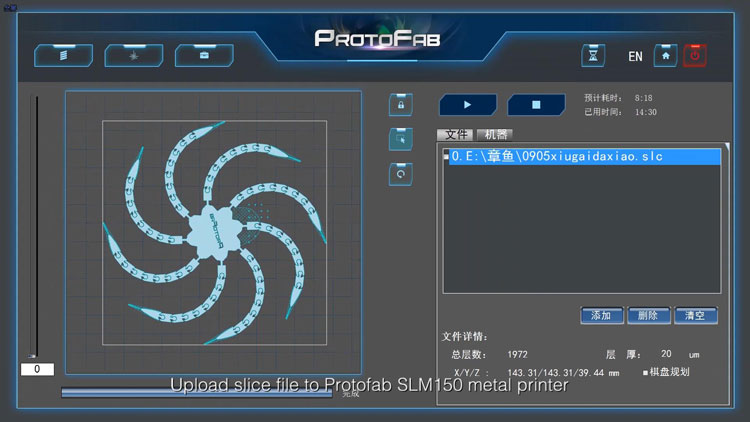

2. After slicing, upload the slicing file to frotofab SLM150 metal printer, program and test the SLM150 Metal 3D printer, and then carry out selective laser melting 3D printing;

3. The powder feeding mode of FrotoFab SLM150 metal printer is single-phase powder spreading by scraper. The solidification speed of laser melting forming area is fast, the printing efficiency is high, and the selective laser melting / powder spreading is repeated many times. So repeat it until the workpiece is formed;

4. After printing, the base plate will be raised, and the excess metal powder on the base plate will be removed. The octopus model with metal base will be born out of the air. 3D printing will be integrated and it is fast.

5. When the metal base is cut, all the joint tentacles of octopus can move flexibly, the shape is lifelike, wear-resistant and fall resistant, with excellent surface printing quality and fine printing effect.

Summary

The metal parts printed by SLM 150, a selective laser melting equipment independently developed by ProtoFab, have high dimensional accuracy, high surface quality and nearly 100% density. Compared with the traditional process, it basically does not need subsequent reprocessing, which can effectively shorten the processing cycle and help customers reduce the development cost. The technology has been widely used in aerospace, automobile, high-end mold and medical and other high-end fields.