Create Time: 01/10/2019

Post-curing is a stage of SLA printing that is often overlooked but which can greatly influence the final properties of a printed part. Post-curing isn’t a one-size-fits-all process. There is skill and experience involved in deciding on the right length of post-curing for different materials and part sizes. For some parts post-curing is essential, while for others it is not important at all. Let’s take a closer look at the science behind SLA post-curing and discuss why it important to get it right.

During SLA printing, specific areas of resin are exposed to a laser which causes them to cure. Once this process is complete the entire part will be cured, so it may not be completely clear why there is a need to post-cure. To answer this question, we have to understand the properties of hotosensitive resin and how it transforms from a liquid to a solid. While in a liquid state, the resin is made up of lots of unbonded monomers mixed with photoinitiators. Exposing this mix to the strong UV light from the laser causes the photoinitiators to react and for the monomers to bond together and form a polymer. This is the primary curing stage. The cured resin is a crosslinked macromolecule, which means that every part of it is directly connected to every other part of it. However, after printing there will still be many sections which are not crosslinked to the extent they could be, which affects tensile strength and other properties. UV light can be used to complete the molecular bonding and make sure every crosslink that could be made is made.

For the purposes of post-curing, the sun is actually not a bad source UV light. Many hobbyists using consumer SLA printers will simply place printed parts outside in the sun for a while and that gets the job done. However, in more professional settings it is generally standard practice to use a UV oven, which is much more controllable.

Post-curing not only makes parts stronger, it also makes them more stable. Having unreacted photoinitiators and unbonded polymers in the part will mean its state could continue to alter long after it is printed, particularly when exposed to sunlight. For parts that need to be precise, such as dental inserts, this is completely unacceptable. Unpainted parts may also change color when exposed to sunlight if not properly post-cured. This is an issue with SLA resins in general but will be more pronounced if the part is under-cured.

The primary reason for post-curing though is usually to increase tensile strength and remove any surface tackiness. Some printed materials may be slightly soft prior to post-curing and weaker sections of the build could sag or droop, affecting accuracy.

There is also a question of safety as uncured resin is toxic to humans. If parts that are not fully cured are handled with bare skin there is the potential for irritation or other issues, particularly if the handler’s fingers later make contact with their mouth. Post-curing a part has the effect of making the resin completely stable and safe to touch.

Fully cured 3D printed part

Curing is affected by both heat and light. Heat increases the energy in the crosslinked polymer network and causes more movement at a molecular level. This increase in energy and mobility makes it much easier for reactive groups to come into contact with each other and for further bonds to be made.

However, UV light is the primary ingredient needed in post-curing. Although the equipment is referred to as an oven or a furnace, in reality the temperatures inside are not high at all, not much hotter than a tanning bed. The resin used in SLA printing is photosensitive and exposing it to light causes a reaction to take place. As discussed above, during the original curing phase of printing not all bonds that could be made are made, and so further reactions need to be stimulated. When exposed to UV light during post-curing, free radicals are formed which bond with nearby groups and create polymerization.

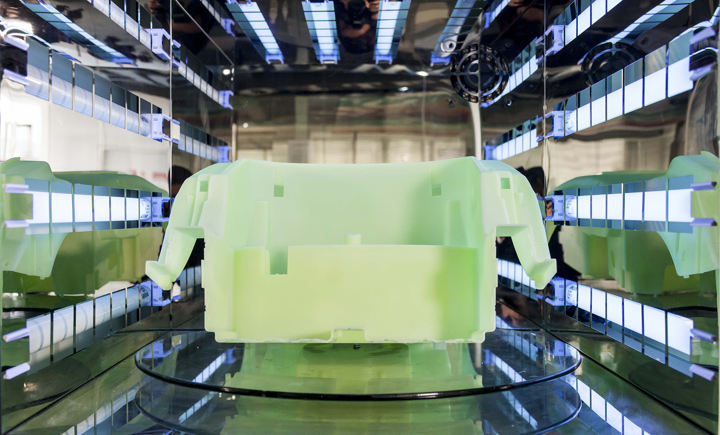

Large automotive part going through post-curing

However, it isn’t the case that the more light you provide the faster the process will be or the stronger the material will become. What is more important is the wavelength of the light used in relation to the resin the part is formed from. Photosensitive resins are designed to react to certain wavelengths of light and using a different wavelength to this in post-curing will give suboptimal results. This is why one of the reasons why professional 3D printing teams use specialist equipment for post-curing. In the case of ProtoFab, our resins cure best using light with a wavelength of 355 nm. If resins from another supplier are used then this value will be different. For example, Formlabs’ resins cure best using 405 nm UV light. This is a very good reason to use ProtoFab’s own UV oven if you are already using ProtoFab supplied resins. Using another type of UV oven or a UV nail varnish curer will promote some degree of additional curing but will not unlock the maximum mechanical properties of the material.

Another issue with using the sun or non-specialist equipment is that the curing will be uneven. The sun will shine more on one side than the other unless you continually rotate it, and the same will be true of nail varnish curers which only project light from the top. Specialist curing ovens generally have a rotating platform or UV bulbs completely surrounding the part in order to ensure an even cure.

The ProtoFab UV furnace comes with each printer sale free of charge

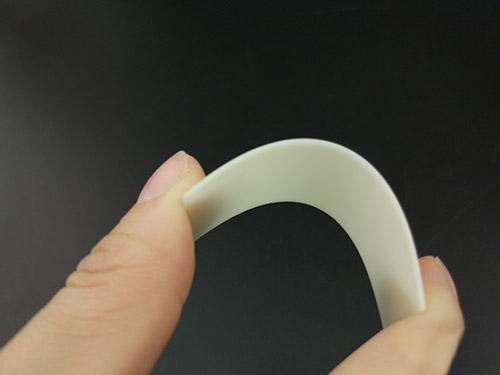

Resins come in many different types and possess a wide variety of properties. As you would expect, this has an effect on post-curing. Materials that are particularly low in strength or high in flexibility often do not require post-curing, or only require a very small amount. Excessive curing of such materials will reduce flexibility and result in them becoming brittle. On the other hand, materials that are selected specifically for their strength or rigidity will require the most post-curing in order to make sure these properties are enhanced.

Post-curing is required for standard SLA materials such as ABS-like resins, although it doesn’t have to be for a particularly long time. At ProtoFab, we generally post-cure ABS-like materials for around 20 minutes in our curing ovens. Transparent materials will require slightly less time, somewhere in the region of 10-15 minutes. ProtoFab’s resins generally all require some degree of post-curing, it is only in unusual cases that we choose not to complete any post-curing at all.

The size of the part is also an important factor to consider with deciding on the length of post-curing. Very large parts will require much longer in the oven, while small parts will be in and out in just a few minutes. This is where the importance of experience comes in. An experienced technician will know the perfect amount of post-curing for parts of different materials and sizes, making sure the mechanical properties of all printed parts remain consistent.

Smaller parts usually require less time for post-curing

Post-curing done well is a quick and simple way of boosting the quality of SLA parts. Parts that are even slightly under-cured suffer from a range of issues and have much lower tensile strength than properly post-cured parts. For parts printed with softer or more flexible materials you may want to be a little more careful, but the vast majority of SLA materials will be improved significantly by spending some time in the curing oven.

The post-curing of parts using flexible materials should be done with care