Exhibition car is may called dream car which custom-made car designed for public display but not for sale.It is usually displayed at auto shows and other exhibitions. This project is independently designed by the Vistar’s design and development team.1:1 solid simulation model made by CNC precision machining and 3D printing for display.

We faced great challenges, not only in terms of manufacturing quantity, but also in a wide range of processes and technologies.

(1)Shape, size, structure, color, even all automotive interior parts...made exactly to the specifications of a real car.

(2)Nearly a thousand parts need to be manufactured and machined.

(3)Covers almost all processes in the RP field, such as coating, hot stamping, color spraying, carbon fiber, cubic printing, CD lines, silk screen printing, laser cutting, spray painting, electroplating, etc.

(4)High difficulty for assembly: The exhibition car only defines the appearance and material, there is no process specification, assembly clearance requirements and other information. To this end, we repeatedly adjust in order to pursue better assembly results.

(5)High requirements for quality: As for the show car, it must achieve zero defects. So we focus on the most vulnerable areas, such as lines, R angles, gaps, surface, electroplating and painting.

(6)Pressed for time: 90 working days is the normal production cycle for this kind of project, but we need to shorten it to 60 days.

Protofab(Vistar)’s ultra-large industrial-grade photocurable printer SLA2400 adopts the world's first DLC (dynamic laser power control) scheme with three mirrors, three lasers and three variable spots. Its advantages over CNC are as follows:

1.Fast printing speed

2.Large printing format and no waste in the printing process, such as printing the entire car grille/ car dashboard/ car front gear/ car interior in one time.

3.The surfaces and details of the printed workpiece are excellent even without post-processing.

4.Process simplification: As long as the STL file is imported, the printer can intelligently analyze 3D data and generate support, and then click start printing.

5.Greatly reduces the development cost and cycle of new products.

6.Parts with complex structures and high precision will not be a problem.

7.Good surface finish can reduce complex post-processing processes, shorten processing time, provide better reproduction appearance and assembly accuracy, and greatly improve efficiency.

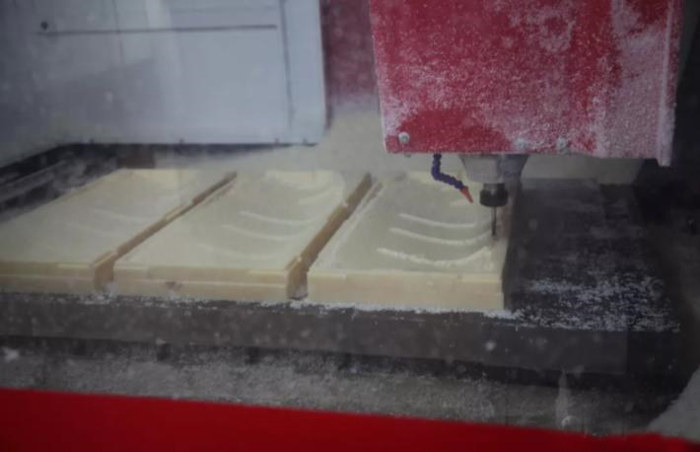

Because high simulation car prototype needs high precision, we will use CNC machining in order to meet the high precision requirements

According to the design drawings and engineering requirements, our automotive production team using welding processing to build a 1:1 body frame.

To avoid interference in the assembly process, we first produce large size parts and assemble them with the body frame, and then adjust the smaller parts according to the semi-assembled body frame.

Automobile painting process is usually done by hand rather than by automated equipment. The general process is grinding, finishing, fine grinding (for R Angle and lines), spraying primer, spraying finish after polishing, then spraying varnish, and finally polishing. The key points are as follows:

1. Varnish needs to be sprayed more than 3 times, so that the paint surface shows a three-dimensional sense and thick sense.

2. For various defects in the spraying process are not acceptable, such as orange peel, particles, pitting, scratches, uneven color, opaque varnish, oil flow, etc.

3. In the light of the test lamp row, the reflected light and shadow should be uniform to ensure perfect performance under the spotlight of the auto show.

After professional grinding, spraying and assembly, all interior and exterior decorations are perfectly matched with the whole vehicle.

Leather coating is the most complicated and time-consuming process in the coating process, because the leather material is soft and has a lot of natural wrinkles and textures. To do this, we compare each piece of leather in every position to achieve perfect look and feel.

Dozens of inspection procedures, from appearance, to interior, to vehicle assembly, do not miss any detail, with the most stringent inspection standards to ensure the "zero defect" of the show car We create the most beautiful show cars with intelligent and precise craftsmanship, so that every user can enjoy the perfect quality. If you have business needs for car-related printing services and 3D printing equipment, please contact us, and we will provide professional solutions according to your needs.