3D Printing Intelligent Remote Control Robot

It takes a lot of time and manpower to manufacture and assemble various parts of robot model manufacturing. 3D printing provides a new mode and opens up a new way of robot model manufacturing. Some foreign creators like to use 3D printing technology to make robots, because it can greatly reduce the cost of production. This issue, I want to share with you a robot and handset model that made by a foreign student. Is it dazzling and cool? Let's take a look at it together.

Model Name: Intelligent Remote Control Robot

Material: Photosensitive Resin

Manufacturing process: SLA laser curing process

Printer Type: ProtoFab SLA600 DLC 3D Printer

Manufacturer: Vistar 3D Printing

Delivery cycle: 3 days

User Requirements: 3D Printing + Post Processing, There is no need of assembly

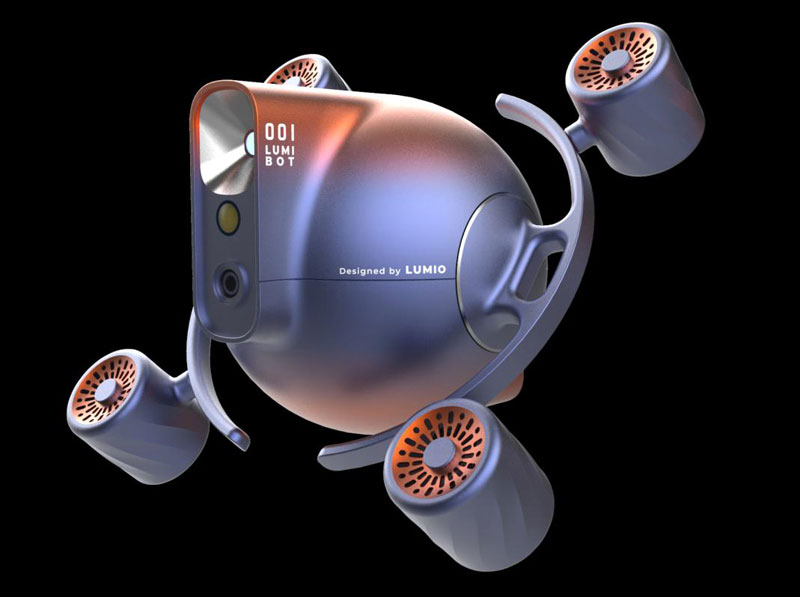

Robot rendering

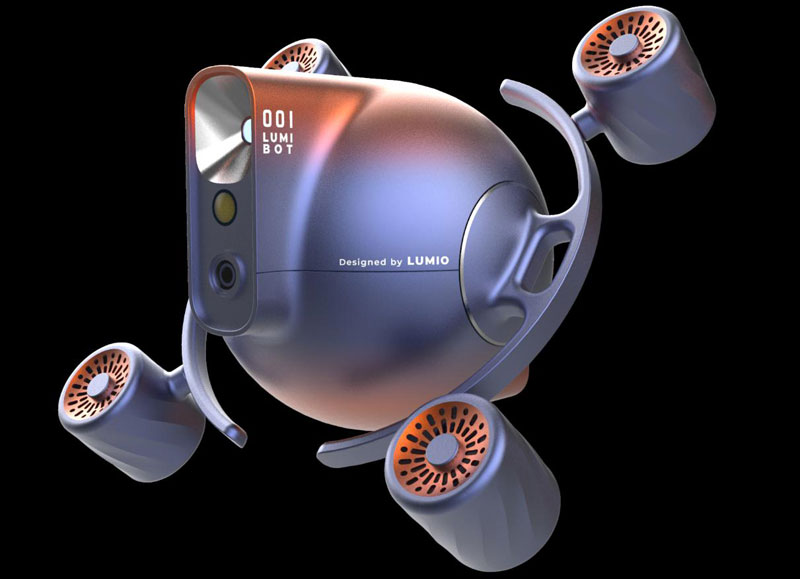

Handset rendering

After understanding the needs of students, the designer of Vistar modified the STL 3D data model provided by students and adjusted it to conform to the structure of 3D printing, then sliced and printed it in 3D.

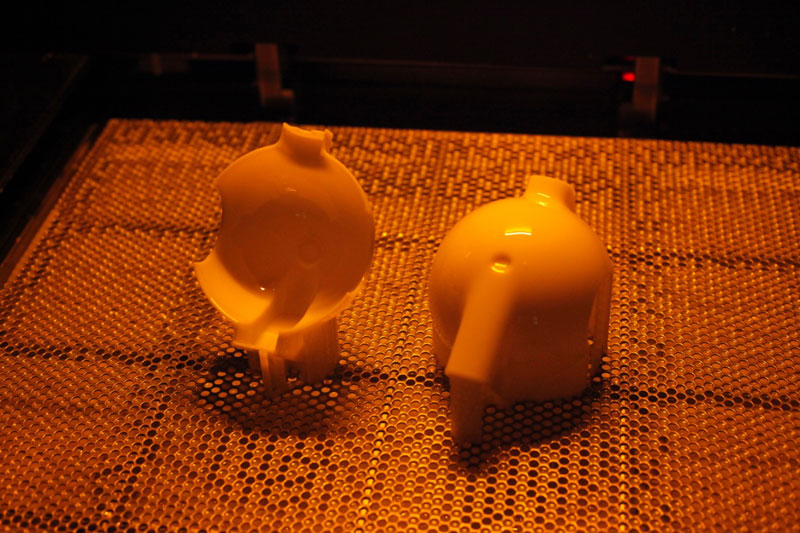

Production process

1.Because of the complex structure of the model, the whole robot and handset model are divided into several 3D printing parts. With the help of software, our professional analysts optimize the assembly of drawings and verify the feasibility of drawings. After the analysis is completed, the files are imported into Magics for slicing.

2. 3D printing: By using the industrial SLA3D printing equipment (SLA600 DLC) independently developed by Vistar and the self-developed high-performance photosensitive resin material, and cooperating with our skilled engineers team, several separated 3D printing parts were perfectly copied. It has fast printing speed, high precision and smooth surface. Compared with the traditional CNC processing method, it has obvious advantages in terms of time and consumables.

3D Printing of Robot Parts

3. TPM automatic cleaning and removal support: After printing, the workpiece is put into an automatic cleaning machine developed by Vistar for TPM automatic cleaning. This equipment is convenient, fast, safe and environmentally friendly. At present, European and American countries have all required the use of such equipment and cleaning methods.

ProtoFab Automatic Cleaner of Vistar

4. Rough Assembly

The assembler with rich experience in model making makes rough assembly of the printed parts. They print out parts with high dimensional accuracy and perfect fit in stitching.

5. Precision Finishing

Grinding - We are perfectionist about details. The process of polishing and spraying is complex and needs to be carried out alternately. The technical proficiency of our operators is highly demanded. It must be sanded from coarse to fine (400-1200) until the surface is more smooth.

Painting - According to the students'post-processing requirements, the sprayer carefully compares the color blocks and sprays the corresponding paint color designated by the customer for each part of the model printed. After spray painting, the color of the car model is bright, and the lines are smooth and dazzling.

6. Silk Printing of Post-processing Technology

Vistar provides a wealth of post-processing technology, which can be used for surface treatment of product appearance, including grinding, sandblasting, painting, polishing, silk printing, electroplating, vacuum plating, flocking, anodizing, radium carving, water transfer printing, etc. The model is silk-printed. After silk-printed words, the whole model looks more dazzling and distinctive.

7. Assembly

At the customer's request, the model does not need us to assemble for it, so we have no pictures of the assembly link here. It's a pity that only a few parts are assembled.

Assembly effect diagram