Prototyping Service Case-Headphones by 3D Printing

Headphones by 3D Printing

Item: headphone

Process: SLA rapid prototyping with polish & spray

Print material: white photosensitive resins with high strength and high toughness

Application: exterior design and structure verification

Service provider: Vistar 3D Printing

Printer model: SLA600 DLC

Manufacture period: 2 days

Project Background

Nowadays, headphones have become an indispensably portable device when we go out. Some people like headphones for its eye-catching appearance, some people love in-ear headphones for its simple look. With scientific- technological progress and the changes of time, the headphones have also been innovated, highlighting the sense of science and technology, focusing on individuation. Compared with traditional processes, the advantages of the 3D printing process are what you want. 3D printing technology has become the trend of the times.

Project Analysis

After receiving the 3D drawings, based on customer's requirements, the preliminary analysts review its process and action, disassemble structure and formulate the production process.

The model of this earphone is much complicated with more corner angles and small parts .If it is processed by traditional CNC, the materials, cost, time and manpower are very huge. After assessment, our professional analysts decided to employ SLA technology(Stereo Lithography Appearance), which can be quickly formed and easily processed through 3D printing.

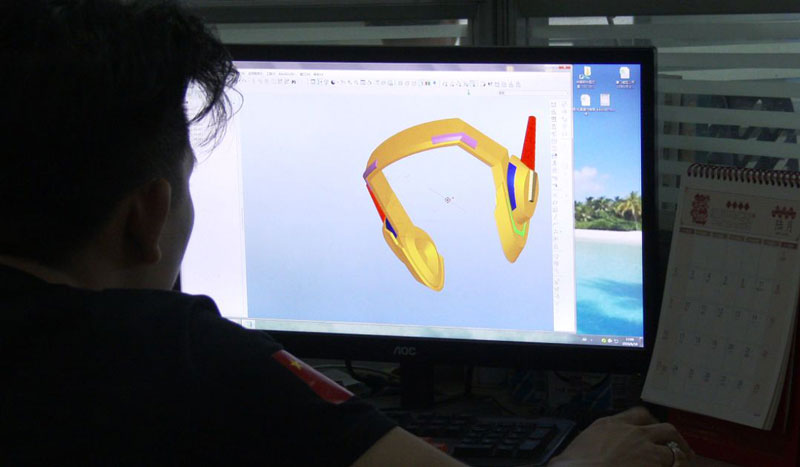

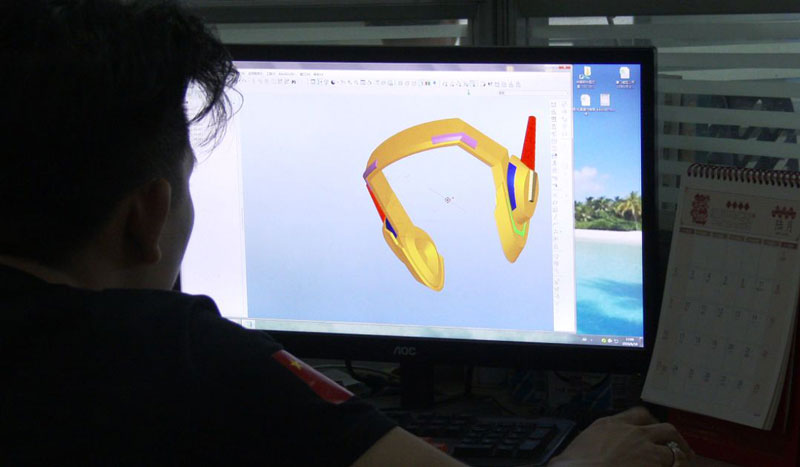

CAD File of Headphone

Selection of ways of production process through preliminary analysis

Manufacture Process

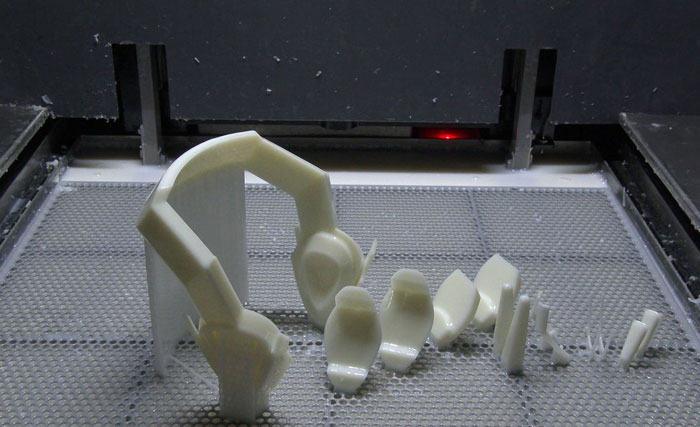

1.when preliminary analysis finished, we need to disassemble and verify parts for integral effect.

Disassembling and verifying component for integral effect is one of important links, since each tiny part would affect the result of the final model assembly.

2.Importing files into Magics software for slicing

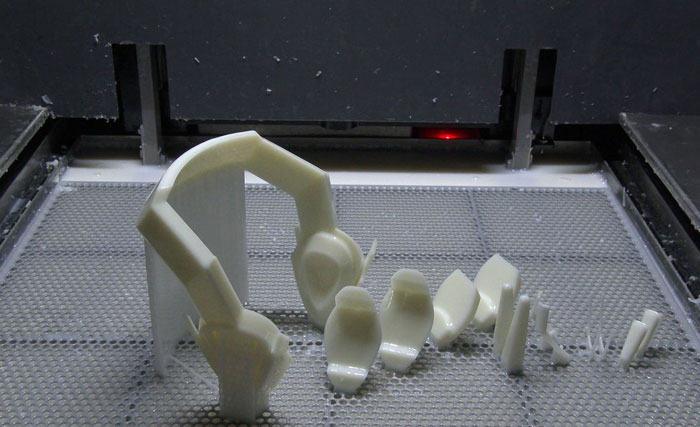

3.Computer Operation and Printing

The cover of this pair of headphones is completely printed by Vistar High Speed & Smart SLA series of 3D Printers-----SLA 600 DLC. We choose SLA 600 DLC for its excellent surface quality and accurate printing effect.

Printer Model: Vistar High Speed & Smart 3D Printer

Considering the elements of structure and appearance of the earphone, we need to choose the proper material with favorable mechanical capacity and high toughness, which can be painted easily. Therefore, we choose the white photosensitive resins with high strength and toughness, which is researched and developed independently by Vistar.

Printing material: Vistar white photosensitive resins with high strength, toughness and precision, smooth and delicate surface and easy post process

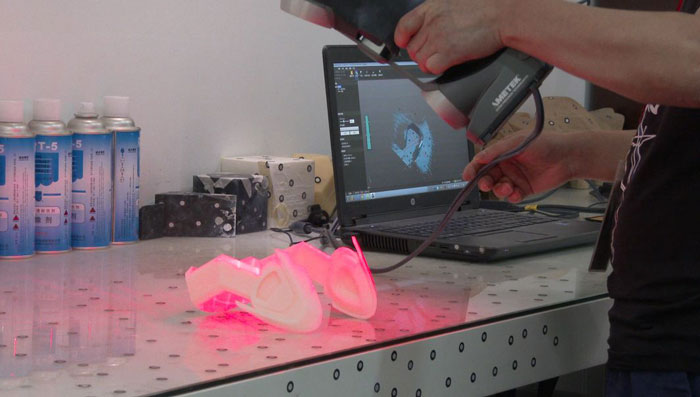

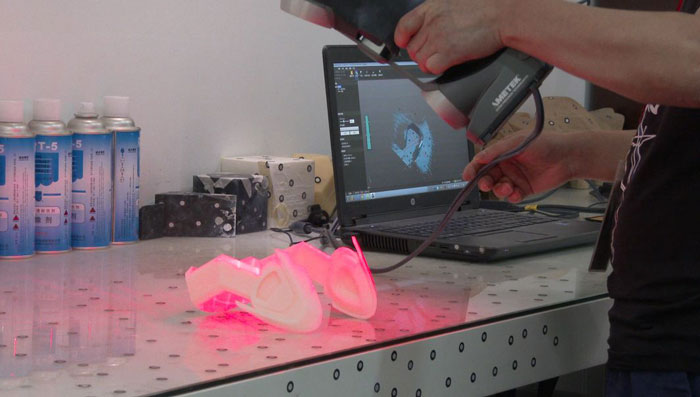

4.3D Scanning: verifying the integral degree of printed parts

3D Scanning: verifying the integral degree of printed parts

5.Verification being completed, the printed parts are moved to post treatment.

Three main steps: polishing, spraying and bonded assembling

Post-processing is critical to the impact of the final model, so each step should be done carefully. Our technicians who have many-years processing experience in prototype have processed the models with skills, and the final products are surprising.

Vistar fully supports personalized customization. Different parts of the earphones can be painted with different colors. Even you can choose the shape of earmuffs as you like.

Precision Polishing Treatment by Hands

Painters blend corresponding colors in accordance with international Pantome color number.After painting, the model has bright and durable color, whose paint would not peel off easily.

Bonded Assembly

6.Exquisite Product

7.Package and Shipment

We can provide clients with CNC machining, 3D Printing, product appearance processing (polishing, vacuum casting, spraying, silkscreen, transfer printing, electroplate, laser cutting, brushing,etc.) low-volume products with personalized customization, mass production and many other services, which can help clients quickly verify appearance and structure of product and realize sample manufacturing and rapid manufacturing with high-quality. If you have the needs above, please contact us!