A: Pre-inspection work

1.1The outer surface of the equipment is clean, free from dust, residue and residual liquid.

2.1The running conditions of each bearing of the equipment are normal, no abnormal noise, vibration, and jitter

3.1The lubricating oil of each bearing of the equipment is brushed normally, and an appropriate amount of lubricating oil is added according to the regulations to ensure that each bearing unit can run smoothly.

4.1The actual instruments of each unit of the equipment are normal, and the control data is normally in the operable state, and to check whether it is within the specified range.

5.1To check if the equipment is safely grounded and whether the contacts are tightly.

B:Equipment environmental inspection

6.1The equipment requires a working environment of 25℃and a humidity of 25%. Because some hardware of the device operates in a high temperature environment and it is easy to affect the printing performance of the device. Some hardware runs in environments with high humidity and it is easily affect the life of the device.

6.2To check whether there is any vibration at the site where the equipment is located.

6.3To check equipment shock absorbing pad, shock absorbing rubber device is assembled properly.

6.4To check whether the device is in a horizontal state

C:Device software check

7.1 To check whether the control software matched by the device and whether it is the highest, and the latest version, and the difference between the versions. In the actual operation of the software, are various prompt questions normal? Does it affect the performance of the product during the printing process?

8.1To check whether the hardware control of the device that the software is equipped with is connected properly.

9.1To check whether the various print information displayed by the software is consistent with the actual device operation

10.1To check whether the software operation data is set completely and reasonable

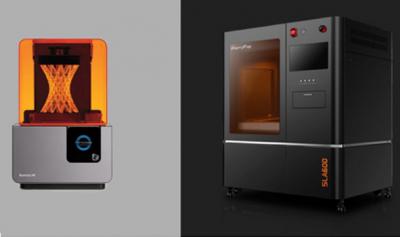

D:Device hardware check

11.1(D1.65-D1.7MM)To check whether the laser setting is stable, what is the damage rate, and whether the spot size of the entire laser system is normal (D1.65-D1.7MM)

11.2 X,Y,Z,R,C。To check whether the X, Y, Z, R, C five-axis operating state is good, whether there is looseness, whether there is damage, and whether the bearing oil maintenance is qualified.

11.3To check whether each module is stable and whether the vibration cause the module loose.

11.4To check whether the scanner is intact.

11.5To check whether heating system stable

11.6To check whether printing platform is losse.

11.7To check whether the air pound loud or leaking

11.8To check whether the air tube is blocked or leaking.

11.9To check whether the operating hardware of the equipment are all intact.

E:Raw material inspection

12.1 To check whether the raw materials meet the standards of equipment usage.

12.2 To check whether the raw materials are regularly filtered

12.3To check whether the raw materials are used for a long time, and need to stir them to prevent precipitation.

12.4To check whether the raw materials have deteriorated

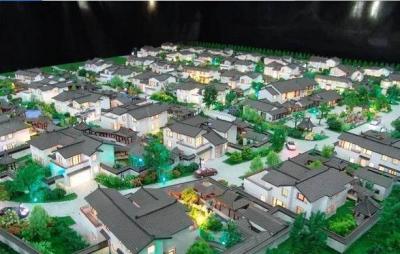

F: Actual printed model checking and analyzing.

13.1 This item needs to be combined with the actual quality of the off-machine product for on-site analysis and confirmation.

G:About the scraper maintenance standards.

14.1;Before disassembling, to confirm whether the scraper is properly adsorbed

14.2:When disassembling the scraper, be careful the screws on both sides of the scraper and it need to be loosened one by one. Make sure the scraper is not curled and does not deform.

14.3:After the disassembly, move the scraperto the cleaning chamber, and then clean the inner and outer walls.

14.4:Upside down the scraper to check whether there are any unpleasant sights, like depressions bosses, curls, etc. on the two edges of the scraper,

14.5:When bonding the resin debris at the bottom of the scraper, use a wooden block to clean the bottom of the horizontal scraper.

14.6:After cleaning process is completed, installed it on the device, and performed the scraper printing test.

The main purpose of equipment maintenance is to ensure the normal operation of the equipment and the quality requirements of the printed products. Reasonable and adequate inspection of the equipment and the maintenance can improve the performance of the equipment, to prevent unnecessary cost waste. It is determined to be a simple maintenance every two weeks, and a thorough per month, to solve the problems of the equipment on-site, to make sure the fully use of the advantages of equipment