Create Time: 11/18/2021

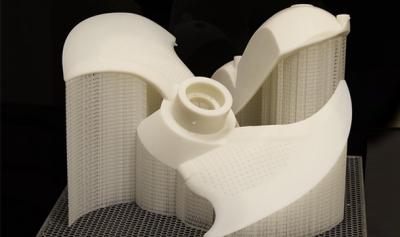

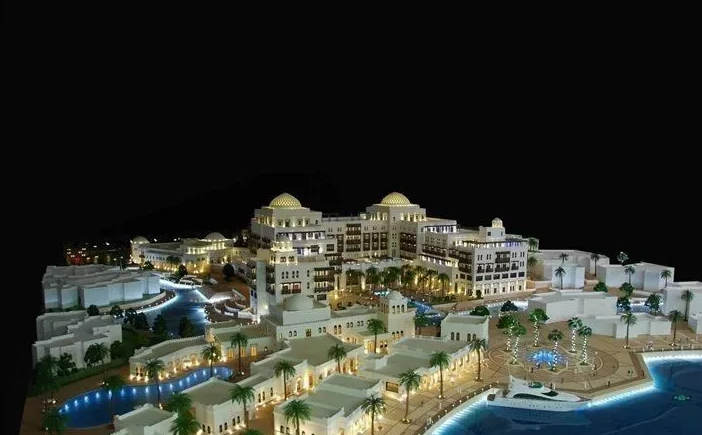

Shortcomings of traditional production methods:Taking the construction industry as an example, the traditional sand table production needs to make a graphic design sketch firstly, the production company designs the structure of the building according to the proportion according to the sketch, then decomposes it into different plates, adds architectural details according to the design requirements, and then sends it to the engraving machine to carve all plates on the PVC plate, finally ,assemble and bond them. The whole production cycle usually takes 1.5-3 months. Advantages of 3D printing architectural sand table: the production cycle of the whole sand table (from design to printing and molding) usually takes only 6 calendar days, which is only 1 / 5 of the time required by the traditional production method (1 month), and the production cost is only about half of the traditional production method. The sand table made by 3D printing technology has the advantages of short cycle, low cost and high precision.

3D printing building sand table is used for industrial manufacturing, looking down at the dynamic system from a macro perspective, controlling the operation mode and grasping the overall trend; Considering the precise time, distance, speed and size from the micro level, accurately grasp the operation model at all levels.So that the real production line can be perfectly reproduced in the virtual environment, the operation of each process is stable, the operation of online and offline is perfectly connected, the production beat is balanced and orderly, and the production line flows smoothly. 3D printing sand table and construction industry

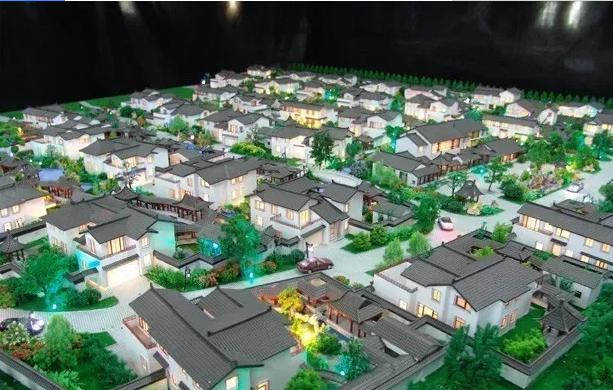

Villa model

Layout of a house model

3D printing technology is a rapid and integrated technology. Its biggest advantage is fast forming speed and high precision, which can almost perfectly present the designer's design. This technology not only benefits architectural designers, but also the whole real estate construction and marketing process is inseparable from 3D printing sand table. Construction personnel can refer to it for construction layout, and marketing personnel can make sand table for marketing publicity, so as to bring users the most direct pre-sales experience.

Education is an important field of 3D printing sand table application, whether for basic education or higher education, whether for students or teachers.

For basic education, 3D printing sand table can not only develop children's imagination and enhance practical ability, but also exercise children's spatial combination ability.

For higher education:

Students of architecture department can use it to easily print out their own architectural solid model.

Geography students can use it to draw real topographic maps and population distribution maps.

Students in the Department of industrial design can use it to print out their own designed workshops and production lines.

For teachers, 3D printing sand table can make teaching more vivid and effective and Increase the absorption and cognition of classroom knowledge.