1. Sirius3D printing control software is the only 3D control software that can be used on the Linux operating system in the world. It has the following advantages:

1). Linux is an open source control software, which is all genuine software, and it is a good control parameter, so there is no need to worry about piracy;

2). The security performance of Linux is extremely high, which makes it difficult for hackers to invade, and the data will not be lost under any circumstances;

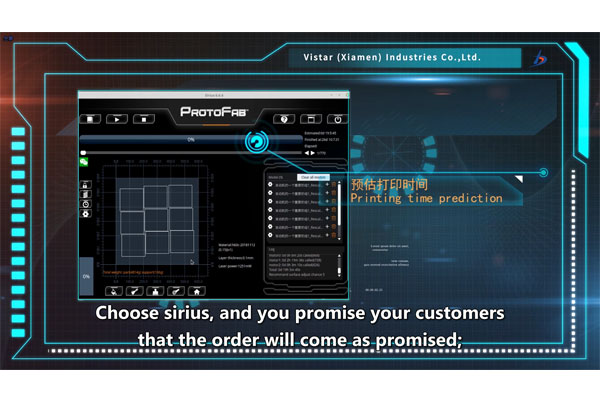

3). Sirius is fast, only 2-8 seconds, 20 to 80 times faster than other 3D printing images, greatly reducing the waiting time of operators.4). Sirius software is accurate in estimating time, which is conducive to the evaluation of quotation in terms of time. The error between the estimated printing time and the real printing time is only between 0.2% and 3.8%.

5). Sirius software, one WeChat can remotely control 100 printers. It can remotely view real-time printing status, statistical materials and printing capacity, greatly saving labor and management time;

Advantages of power printing technology

2. The speed of 3D printing is the most important technical index at present, and speed is the guarantee of efficiency. The DLC variable laser power printing technology pioneered by ProtoFab has the following advantages:

1). Fast printing speed, two to five times the speed of other brands (fast physical printing speed), one machine is equivalent to more than two machines of other brands, which greatly improves the printing competitiveness and production efficiency, and greatly improves the economic benefits;

2). The printing weight of the single galvanometer is three to five kilograms per day (more than the physical printing weight).

3). High printing precision and surface finish

4). High printing success rate

3. Simple interface, a key fool operation, simple and easy to use

1). The interface is simple, simple operation, junior high school graduates can master the software operation in 20 minutes.

2). Established a full range of material database, intelligent export operation mode, and selected three intelligent printing modes (standard printing mode, quality first mode and speed first mode); This makes programming easier, and junior high school graduates can be fully qualified for the job with only one day of training, greatly reducing the requirements for printing operators. This is convenient for enterprises to recruit, but also can effectively reduce the cost of employment, improve corporate profits.

4. Industry 4.0 intelligent manufacturing high-end equipment

1). Automatic feeding, farewell to manual feeding trouble;

2). Automatic induction open and close, can prevent resin through the hand resin to the machine caused by dirty, not easy to do health, easy to make the staff tired;

3). Automatic detection of laser power: when the power is insufficient, the laser window will not open, unable to start printing, it realizes the self-diagnosis of machine intelligence and avoids a lot of waste caused by the failure of laser power printing.

4). The machine intelligent sensing temperature and humidity, no longer need to buy a thermometer and hygrometer;

5). Remote viewing, you can see the whole printing process with the mobile phone, no need to guard;

6). Remote control, the phone can be transmitted through the Internet programmed, start printing, end printing, greatly saving labor; It can reduce the number of programmers and enable employees to work more freely, satisfying the idea of de-centralization and de-organization in industry 4.0.

7). Provide intelligent continuous additive manufacturing intelligent management software for free, automatic order distribution, automatic statistical data, and market and industry analysis;

8). B2M printing service quotation system is provided free of charge, which can completely eliminate quotation staff and enhance customers' wonderful experience.

ProtoFab: quality and experience in ProtoFab

Technology innovation, good user experience, is a long - term unremitting pursuit of ProtoFab! New and upgraded ProtoFab SLA series products, from software to hardware, improve configuration, greatly optimize performance, more convenient control, it also integrates many humanized auxiliary functions such as power off, automatic feeding, intelligent induction and remote control. DLC variable laser power printing technology, the world's first DLC variable laser power printing technology, makes the efficiency, productivity and quality of the existing record of similar technology. It brings better 3D printing user experience to designers, processing and manufacturing enterprises, shoe industry, medical and other professional users. Nowadays, with its high quality, easy operation, high cost performance and good user experience, etc.

The SLA products of ProtoFab have won a good reputation among customers at home and abroad. Products are exported to the world, the international market share is expanding! For the future, we are full of confidence!