Create Time: 06/01/2019

On May 27-31, 2019, the ProtoFab Russian agent brought the ProtoFab Popularest product SLA600 DLC to the 2019 Russian International Machine Tool Show Metalloobrabotka. Metalloobrabotka is a large-scale and influential machine tool exhibition in Russia. It is held annually by the Russian Machine Tool Association and Expocentre Exhibition Center. It displays new equipment, engineering technology, development and service in various fields of machinery manufacturing. It reflects the status quo and prospects of the machine tool manufacturing industry, determines the creation of advanced technology and the design trend of metal processing equipment, and is one of the top ten industrial exhibitions in Europe.

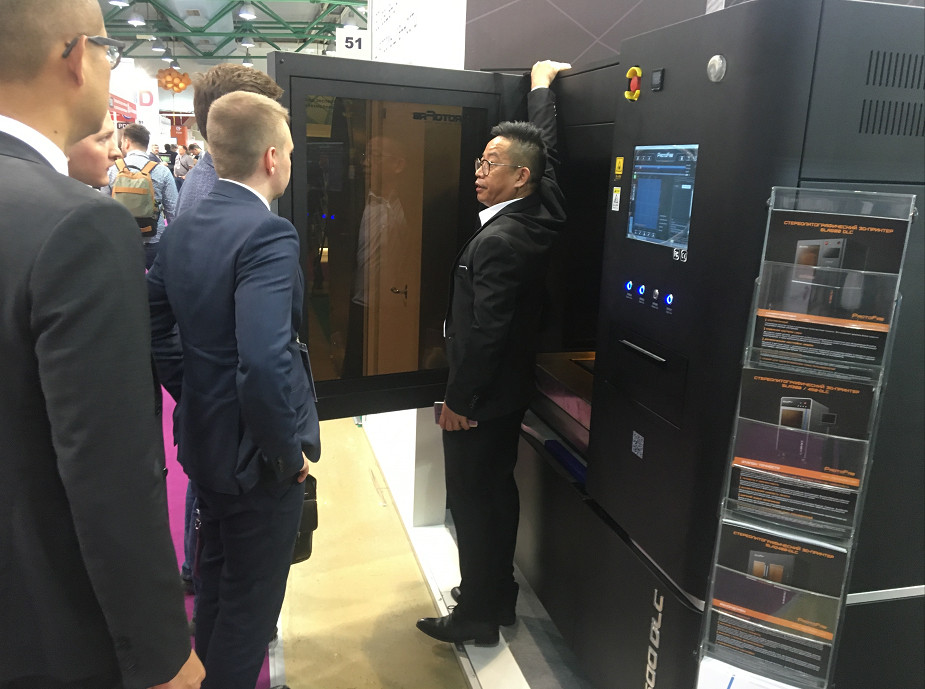

ProtoFab's Russian agents presented ProtoFab's cutting-edge technologies and solutions in 3D printing in a comprehensive and multi-faceted manner, presenting ProtoFab 3D printing solutions for use in a wide range of applications. Mr. Wu Guobao, Chairman of Duch Group, also went to the Russian exhibition site to assist Russian agents.

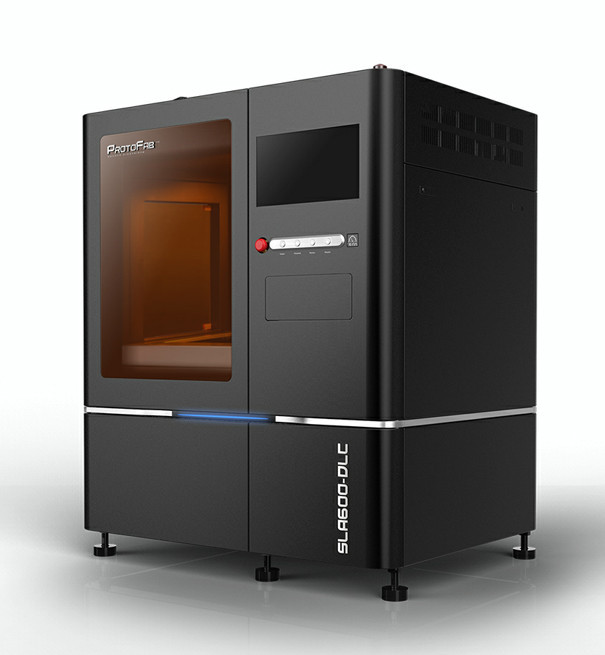

The simple and generous booth design, together with various brochures, the stylish ProtoFab SLA600 DLC attracts many customers to visit 、communicate and negotiate.

The printed parts showcased the different performance of 3D printing materials independently developed by ProtoFab to customers around the world.

Mr.Wu explained the advantages of ProtoFab SLA3D printing equipment to customers, starting from 3D printing hardware equipment, 3D printing control software, 3D printing materials, 3D printing services, etc., and in the meantime, he also introduced the advantages of ProtoFab

world's first DLC dynamic laser power printing technology .

During the exhibition, the booths were full of visitors and the transactions were active. The Russian agent team demonstrated excellent customer service capabilities, and enthusiastically treated every customer who came to inquire, providing professional explanation and caring service all the time.