Create Time: 06/22/2022

There will be a stage of small batch production to test product performance and market demand before mass production generally. If it is a small batch trial production, vacuum casting is the best choice.This is particularly suitable for complex products One-time molding. The strength and hardness of vacuum casting products is similar ABS. It can also be made with colors according to customer requirements. Therefore, it is suitable for plastic small batch production in the product development process.The produced plastic parts are close to injection molding products. Vacuum casting shorten the development time and save R&D cost, which is the best choice for small batch production.Let's learn the production process of vacuum casting now.

First, we will use 3D printing technology, such as SLA (stereo light curing) to print a sample according to the customer's 3D CAD design drawing.

3D printed prototype

The printed sample will be post-processing such as grinding and painting.etc, to make the surface more better and smooth.

These surface features of the sample will be copyed into a silicone mold.

Prototype grinding

We need to make the hoarding of the mold according to the size of the sample. Then pour the liquid silicone into the positioning plate.

Make mold coaming

![]()

Make silicone mold

There is air in this processing.Therefore, it is necessary to carry out defoaming treatment in a vacuum machine.

![]()

The silicone mold is put into the vacuum molding machine

![]()

Silicone mold defoaming treatment

Taking out the hoarding plate after defoaming and put it in the oven for curing.

Silica gel mold curing

Taking out the hoarding plate after curing and start to open mold. After removing the positioning plate, pulling out the positioning pin, and taking out the sample, you will get a silicone mold with front and rear mold cavities.

![]()

Remove the silicone mold inside the prototype

![]()

silicone mold finished product

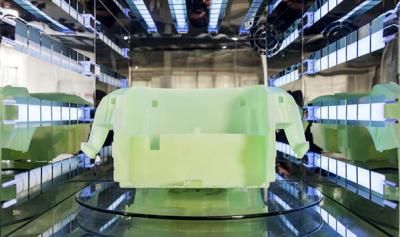

Then you can use the silicone mold we made for vacuum casting. It should be done under vacuum conditions. Pouring the material into the mold by using the air pressure difference. It needs to be cured in the oven after pouring. Then take the product out of the mold. Next, we only need to repeat the vacuum casting process to realize the small batch production.

Vacuum casting

The products produced by vacuum casting is almost the same as the mass-produced injection molding products. After the products are produced by vacuum casting, we have a variety of post-processing processes that can make the products more perfect.

![]()

Prototype made of silicone mold

Vacuum casting provide customers with a wider range of production options. The vacuum casting can produce small batches of various complex parts. It is an excellent low-cost way to produce small batches sample products. The range of application of the vacuum casting is very wide, from small gears to large automobiles and medical parts. The material of the product can be: ABS, PP, PC, PMMA, POM, high temperature resistant material, soft rubber, silicone rubber, etc.

If you have this requirement, please contact our professional team at [email protected] or contact us by visiting our website, we will provide you with a quote for free for the first time.