Create Time: 05/13/2020

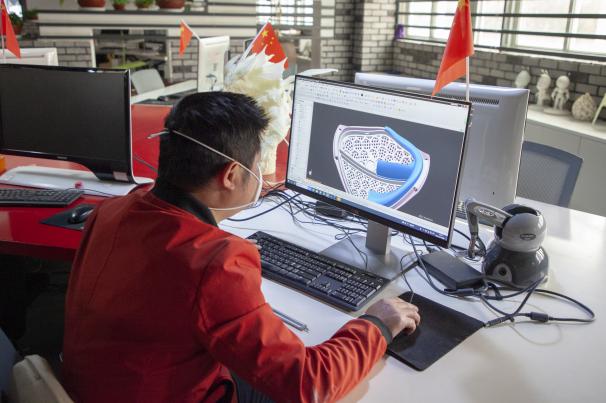

2020, when the new coronavirus turned from a national disaster to a global disaster, masks and other protective equipment have become necessary for epidemic, Vistar (Xiamen) Industries Co., Ltd. began to launch the mass production plan of complete isolation of nose and mouth mask.

Based on the principle of breath filtration of human beings, the structure of nose and mouth separation mask is designed, which makes the gas inhaled by nose and mouth enter through the filtration unit in one way, and the exhaust gas is discharged in one way without interference. It not only completely eliminates the trouble of breath, but also reduces the secondary pollution caused by harmful bacteria in mouth being inhaled by human body again. The efficiency is 1.5-2 times that of traditional masks.

At the beginning of the product, in order to meet the original intention of simple assembly and convenient filter replacement, modular design is adopted. Because the mask has the characteristics of airtightness, it needs to repeatedly verify whether the designed model fits the human face shape.

The production cycle of traditional prototyping needs to be based on the 3D drawings of products and the production requirements, such as materials, processing methods, quantity, surface treatment process, etc., generally about 3 to 5 days. If the structure is complex, the processing is difficult, the time will be longer. But time is money.

Vistar (Xiamen) Industries Co., Ltd. takes advantage of its sla-3d printers, abandons the traditional prototyping production steps, and uses 3D printing technology to verify the design effect.

It only took more than 4 hours from the beginning of model printing to the end of final product, compare to the traditional prototyping processes, the time was reduced by nearly 10 times or more.

Through repeated verification of 3D printed model, the 3D drawing of nose and mouth separation mask was finalized and the ready for tooling and massive production. (see "GUARDIAN Anti-Haze Mask" for details)

16 days from product design to model verification, and then to mass production. Especially in the model verification stage, repeated verification took less than a day. If the traditional way of prototyping is adopted, it may not be taken down for half a month.

The most outstanding advantage of 3D printing technology is that it can directly generate parts of any shape from computer graphics data without any machining or any mold, thus greatly shortening the development cycle of products, improving productivity and reducing production costs. Compared with the traditional technology, it reduces the cost and material waste by abandoning the production line. In the case of good design concept and design process, 3D printing technology can also simplify the production and manufacturing process, and quickly, effectively and cheaply produce a single item.

After a long time of precipitation, 3D printing technology has become more and more mature. It redefines creative design. Both in industrial design and art design can be regarded as revolutionary progress, and will continue to break through, bringing greater changes to various industries.