Current Situation of 3D Printing Material Industry

In SLA resin industry, most of them are white products. However, due to the high requirements for transparency and colorlessness, the problems such as bubbles are prone to occur in the forming process can not be solved, and colorless and transparent SLA resin is relatively rare at home and abroad. This market has been monopolized by a few foreign manufacturers of 3D printing materials such as DSM, SOMOS, 3D Systems and so on. Their high prices have resulted in high cost of 3D printing products and seriously affected the process of industrialization.

Therefore, with the rapid development of 3D printing and printing, it is necessary to develop a transparent SLA resin with good transparency, whose color is pure and close to colorless. It can quickly eliminate bubbles. Its successful launch can play a good role in promoting the rapid development of the whole domestic 3D printing industry, so that China will not be left behind by developed countries such as Europe and the United States on the road of industrial 4.0 revolution. At present, all transparent SLA photosensitive resin materials abroad have some problems more or less, such as bluing, yellowing, excessive water absorption or insufficient transparency.

ProtoFab transparent SLA resin Clara A:

ProtoFab has made innovative breakthroughs in the field of SLA resin 3D printing materials with its strong technical strength and years of dedicated research, starting from the market application needs. It breaks the monopoly of foreign companies on materials and greatly reduces costs.

Through a large number of experiments, the ProtoFab material research and development team selected hundreds of spare formulations to develop transparent SLA material Clara A. This material is characterized by excellent transparency, excellent waterproofing and dimensional stability, non-yellowing, and it is easy to use and rapid production. There are no bubbles in the forming process. The printed products have fine surface, precise size, and enough toughness and strength to ensure that the material has good impact resistance.

Application: Production of automotive, electronic, lamps and other components;

It can be used for occasional production activities such as lens, packaging, fluid analysis, RTV mold turning, durable conceptual model, wind tunnel testing, etc.

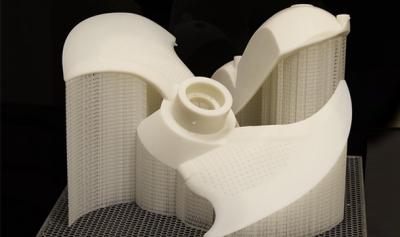

ProtoFab Printing Case

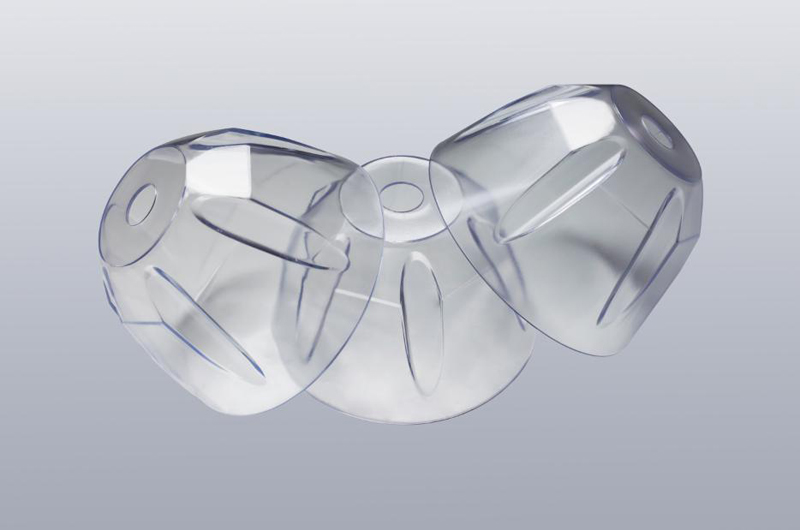

▲Container (fully transparent effect, completely water-tight)

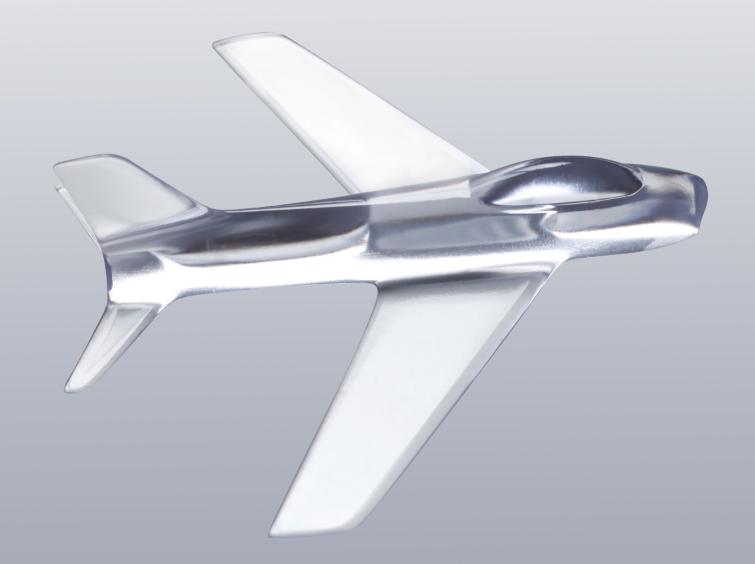

▲Aircraft Model (Semi-permeable Effect)

▲Aircraft model (full penetration effect, transparent parts can be superficially colored)

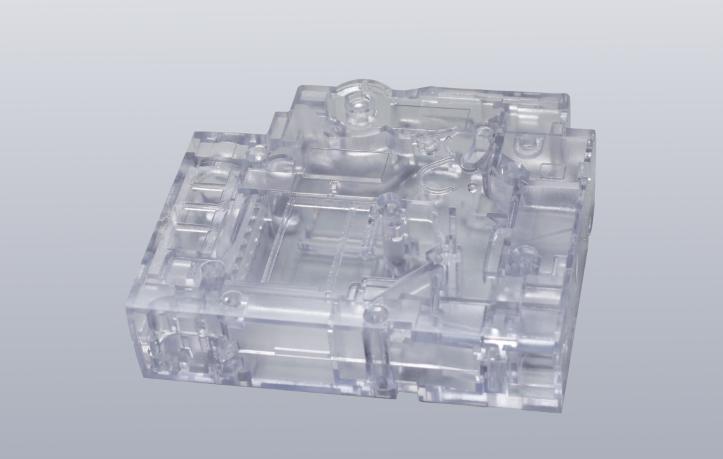

▲A model of an appearance test piece (transparent parts facilitate observation of internal structure)

▲Dental Model (Transparent Effect)

▲Down State

▲ProtoFab Industrial High Speed Intelligent SLA3D Printer

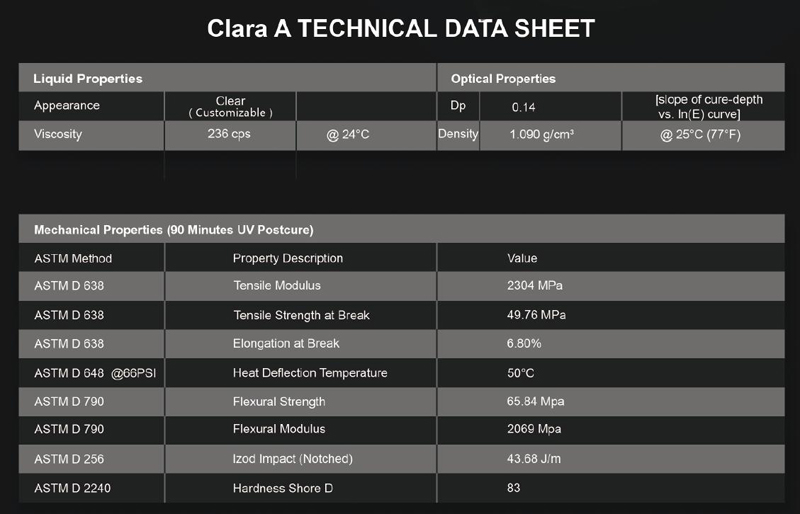

Clara A Material Physical Properties

ProtoFab has established a research and production base for 3D printing materials, focusing on the independent research and development, production, application and service of domestic 3D printing materials, and has realized the strict quality guarantee of 3D printing materials from research and development to production. At present, more than ten kinds of photosensitive resin printing materials with different properties have been independently developed. In the future, we will continue to make breakthroughs and innovations, develop more high-quality special materials, and promote industrial application.

Welcome customers to inquire!